An Introduction To Alanka Laminate Floor

Alanka. Germany technology laminate floors, followed the step of VolksWagen and Audi Car Industry, we started our new factory production in year 2007 at China our product are quickly becoming the flooring of choice for families, contractor, commercial and hotel industry use in Asean market. If you love the gorgeous look of a wood but worried about high expensive sofid wood cost. ALANKA laminate flooring is probably the best option in the market. One of the few disadvantages to a laminate flooring is that it cannot be refinished, sanded or stripped, for water caution, all kind of laminated base flooring are not recommended expose to large quantity of water more then 2 hour, however with good care, there’s not much chance you’ll ever need to replace your laminate floor

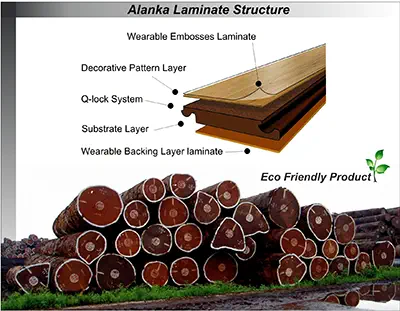

Alanka Laminate Structure

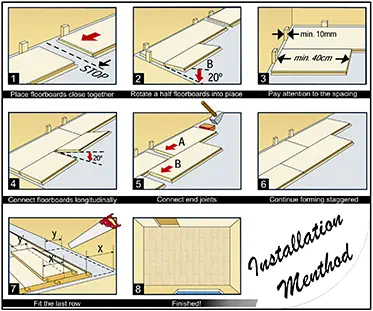

Wearalle Embosses Laminate A transparent layer which Is pressure, stain, scratch and wear resistant to protect the surface. Decorative Pattern Layer A layer that shoes directly the color of wood. 2-Lock System Powerfull lock system design for easy installation, and gain all the surface strenge. Substeate Layer High density fiberboard compress from wasted wood substrate, make to eco friendly. Wearable Backing Layer Laminate A transparent layer ecund insulate and to protect the back surface. Alanka Laminate Installation Method All ALANKA laminate flooring is installed as a ‘floating” floor meaning it is laid on top of your existing surface without being glued down or atthed in any way. When you fit together your planks, you must remember not to make a perfect wall to wall ending, leave a 1/2″ inch gap along all walls to allow for any expansion caused by humidity and heat, and cover the gap with baseboard moukling and skirting. What You’ll Need To Install ALANKA ALANKA laminate floor board PE loam underlayrnent Plastic sheeting It iritalling over ground flour concrete Duct Tape Installation kit pull bar, tapping block, spacers Handsaw or a carbide-tipped blade installed on a power saw, flush-cut saw for undercutting door jambs Threshold Mallet Waterproof silicon glue and green nail silicon.

| TECHNICAL SPECIFICATIONS | |||

| Glue Free lnstal ation – 8.3mm AC 3 ALANKA Laminate Flooring | |||

| Production Method | Production Method | ||

| Surface Texture | Surface Texture | ||

| 1 | Thickness of the element | EN 13329 :2006 | t max – t min 0.50mm |

| 2 | Heightdiffrent between element | EN 13329: 2006 | h max ≤ 0.15mm |

| 3 | Abrasion class | EN 13329 : 2006 | AC 3; IP-value :≥ 2000 revolutions |

| 4 | Static indentation | EN 13329 : 2006 | No visible change, i.e.≤ 0.01mm indentation using a straight steel cylinder θ = 11.30mm |

| 5 | Dimensionariations after changes inTative humidity | EN 13329 : 2006 | σl average ≤ 0.9mm σw average ≤ 0.9mm |

| 6 | Light fastness | EN 13329 : 2006 | Blue woci scale, not worse than 6, Grey scale, not worse than 4 |

| 7 | Resistance to cigarette bums | EN 13329 : 2006 | ≥ Grade 4 |

| 8 | Resistance to staining | EN 13329 : 2006 | 5, group 1 and 2 4, group 3 |

| 9 | Effect to furniture leg | EN 13329 : 2006 | o damage shall be visible, tested with foot type 0 |

| 10 | Effect to a castor chair | EN 425 | No change in appearance or damage |

| 11 | Thickness swelling | EN 13329 : 2006 | ≤ 18.0% |

| 12 | Surface soundness | EN 13329 2006 | ≥1.00N/mm’ |